About Us

Welcome to Therm Transfer Equipment Pvt. Ltd.

Therm Transfer Equipment Pvt. Ltd. Established in year 2000. We have team of experienced engineers, supervisors & Welders. Majority of our work, we are fabricating under third party inspection, we are doing work under M/s. Bureau Veritas, M/s.Bureau Veritas, M/s. LIoyd’s Register Asia, M/s. Toyo Engineers etc…

In last twelve years we had Fabricated Heat Exchanger like, Process Heat Exchangers, Finned Oil Coolers, Finned Heat Exchangers, Inter coolers and After Coolers, Air Pre- Heaters etc…

Generally, we are fabricating shell and tube type heat exchanger, finned type Heat Exchanger and Pressure Vessels. +We are using integrally finned tubes, G-type finned tubes, spiral wound finned tubes etc. We have qualified welder’s and all our welding are of rad.iographic quality. Mostly we done work as per approved QAP and drawing. We strictly follow all engineering codes.

We are fabricating equipment in carbon steel, stainless steel etc.. we are using SA 179, SA 334, SA 210, SA 213 TP 304, 304L, 316, 316L SS 347 etc. tubes . we are also using Copper, Brass, cupronickel etc tubes. We are also doing Re- tubing of Heat Exchanger. We had retubed almost 100 Heat Exchangers. We had carried out lot of Re- tubing for M/s. Gujarat Fluorochemicals Ltd, M/s. Nirma Limited etc…

Following facility available with M/s. Therm Transfer Equipment Pvt Ltd.

Area = 2400 mt²

Constructed work shop area = 400 mt²

Office space = 150 mt² Overhead Cranes = 10 TON capacity – 2 Nos.

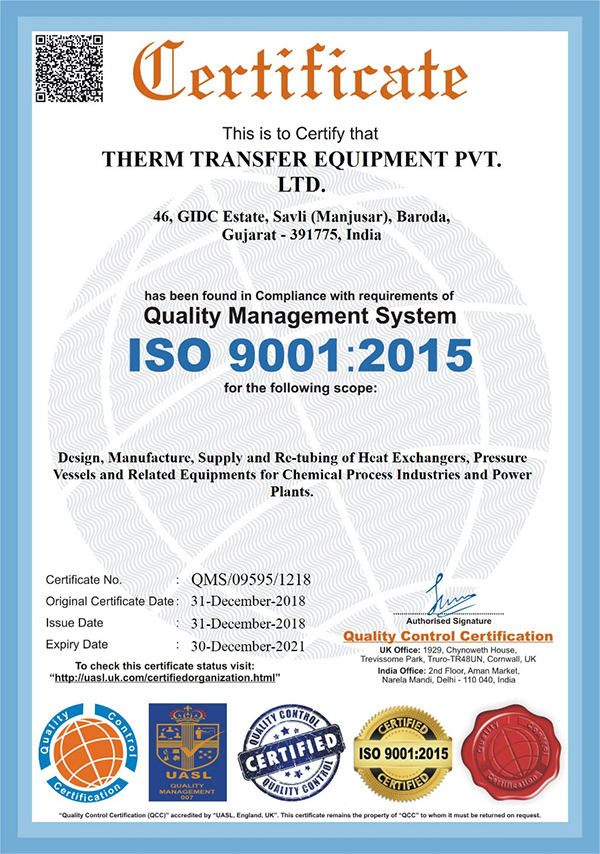

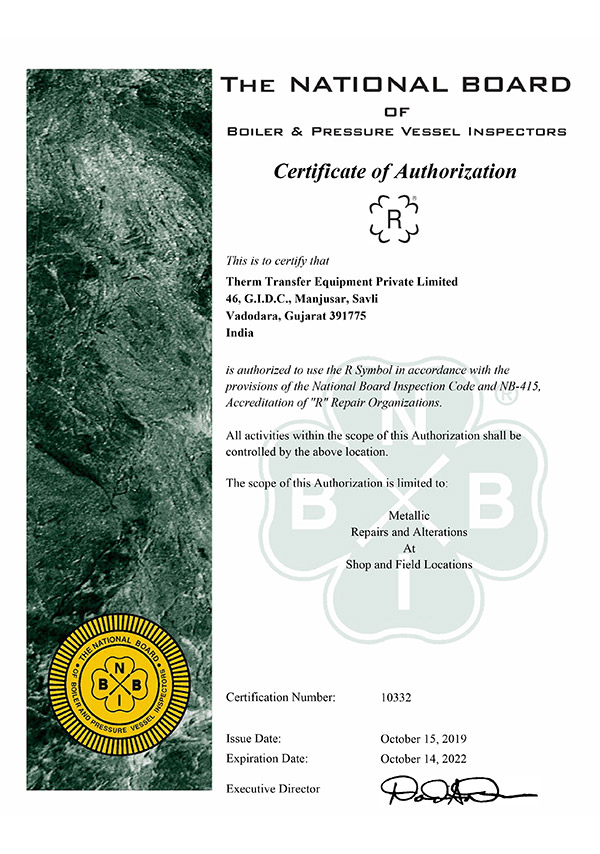

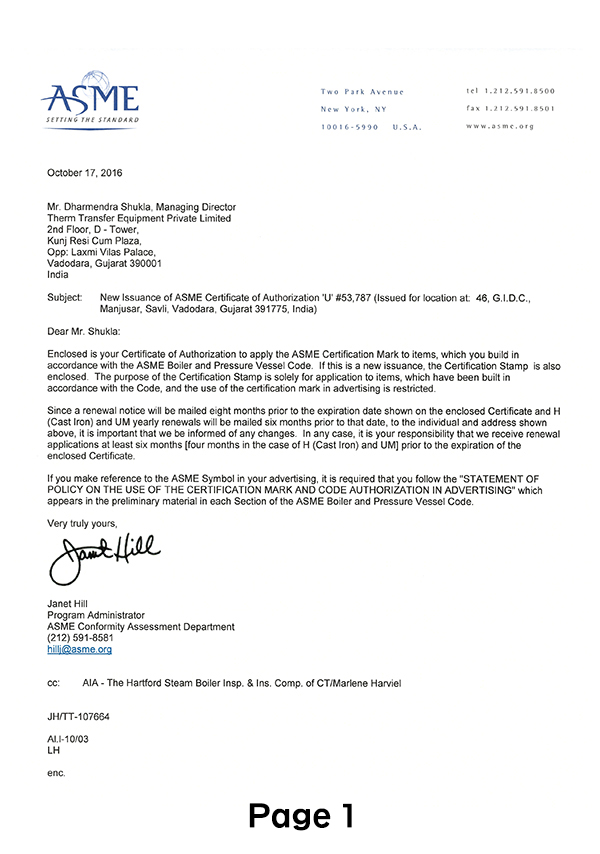

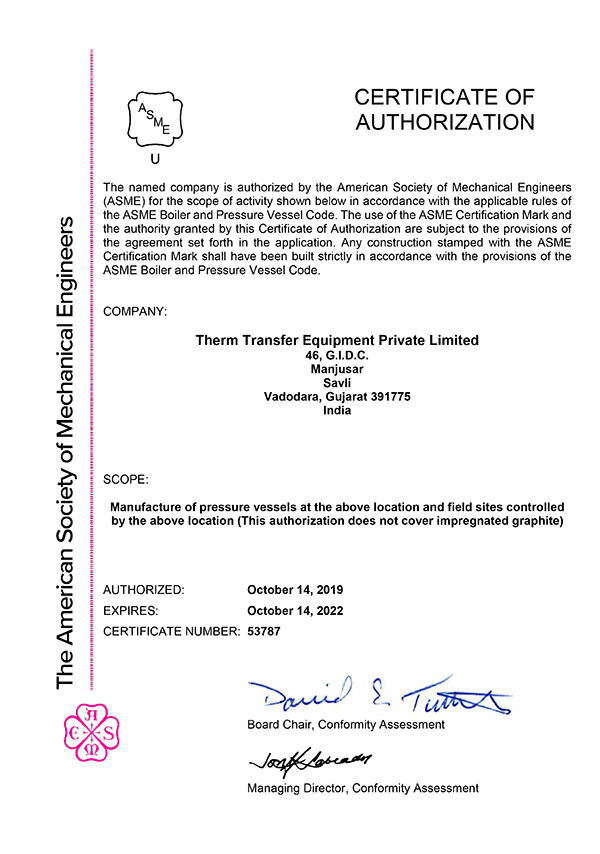

We obligated to meet the quality standards as per the customer Demands